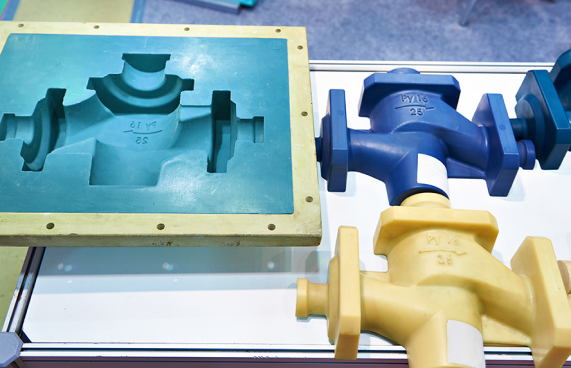

RUBBER/SILICONE

EZ-Kote’s mold release agents for rubber provide unequaled ease of release to achieve less scrap and more pulls per mold.

WHY CHOOSE OUR MOLD RELEASES?

EZ-Kote saves your company money by keeping molds cleaner for longer, whether you use injection or compression molding, or silicone rubber extrusion.

- Water-Based

- Anti-Stick & Anti-Tack

- Silicone, Elastomer & HNBR

- Decreases Degradation of Molds

“RS3A mold release works very well and is very durable for release of silicone, there is no sign of release transfer to the molded product or any surface change which is common with other mold releases. There is no touch up needed for good release. After four hours of running there was no noticeable change in release and believe it was not necessary for touch up.”

silicon rubber, single cavity injection mold, 1045 steel with a standard machine finish

“R2SZ – The pieces came out without any problem in production, without spots , even tested in the process in which they present the most difficulty in production. It was used in the form of a sacrifice release agent. The Production Manager’s comments were positive for the performance of the product.”

natural rubber (anti-fatigue mat),

compression molding, steel

“R10SZ – We are currently promoting EZ-Kote products that we received as samples. Among those products, R10SZ is ‘leading’ compared to competing release agents.”

“MLEX-2 aerosol proved very

successful for our application.”

cast urethane, open cast molding, steel

CONTACT US

We serve the rubber industry with pride. Our mold release agents help save you money in a variety of ways. Talk to us, and we’ll send you a free sample to use on your pilot lines as you research and develop better methods of improving your SKUs while reducing downtime and producing less scrap.