Tire manufacturing continues to evolve and improve. With new materials, manufacturing methods, and process improvements, companies are making the industry more streamlined and eco-friendly. Rubber and tire manufacturing looks to take off in the next decade as more electric vehicles and heavy equipment come online. EVs are heavier than internal combustion vehicles, which means car owners will need to change their tires more often.

In this blog, we will explore some of the key ways to improve your tire manufacturing process while optimizing your bottom line.

Related Post: Rubber Anti-Tack Agent FAQs

1. Quality Control

The quality of your tires is critical to your success in the market. A robust quality control system that ensures all your products meet the highest standards for safety and durability. This means checking the raw materials, inspecting the manufacturing process, and conducting final product tests.

Make sure you have the right blend of software, tools, and human-based visual inspection processes to detect any defects before they ship to the buyer. This process includes knowing how well your anti-tack agents are operating.

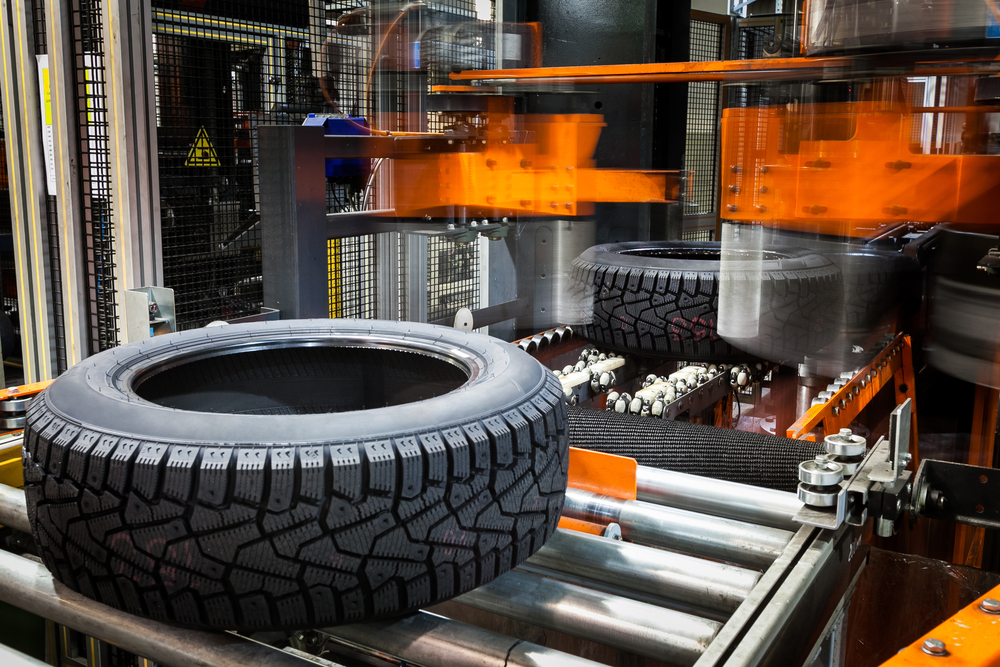

2. Robotics & Automation

Advanced technologies such as artificial intelligence and machine learning offer ways to advance your facility automation. Consider machines that can learn about your rubber manufacturing processes on the fly, allowing the machines to make adjustments while production happens. Find a system that gives you the ability to scale up when you add a new dimension to your process, such as changing or adding an anti-tack agent to your tire manufacturing. Rather than specialized robots, look for robots that can do more than one task at a time. Consider IoT devices that monitor all points of the industrial process, giving your analytics software even more data points when deriving insights into your tire manufacturing operation.

3. Lean Manufacturing

Lean manufacturing minimizes waste while maximizing productivity. Conduct an audit to find areas where you can improve your processes, whether you have too much raw material or discover suppliers are inefficient. Once you’ve identified the areas of improvement, you can start implementing changes to streamline your production process. Procurement software, platforms, or systems that gather data from all points of your operations can identify areas where you can improve.

4. Supply Chain Management

Your supply chain is critical to the success of a tire manufacturer. You’ll need to find suppliers that provide high-quality materials at competitive prices. Beyond building strong relationships with your steadies, diversify the supply chain when possible. If any suppliers can’t come through, you’ll need to rely on others to get you the materials you need.

5. Employee Cross-Training

Cross-training employees is important because it allows you to improve your labor costs. If someone calls in or leaves, someone else can help until you hire a replacement. Your team also contributes to your workers’ knowledge throughout the tire manufacturing process. For example, you train everyone in the plant to operate any part of the plant, from forklifts and moving products to operating every machine on the line and even order fulfillment.

6. Continuous Improvement

Continuous improvement is a key principle in manufacturing, and it’s essential for achieving long-term success. By continuously evaluating and improving your manufacturing processes, you can stay ahead of the competition and meet the changing needs of your customers. Perform audits regularly to improve your operations. You might find ways to reduce bad SKUs, achieve less waste, and economize your products. One way to improve your process is by utilizing the right anti-tack agent at the start of the line.

We Supply Quality Anti-Tack Agents

EZ-Kote has more than 30 years of experience with anti-tack agents for the rubber industry. Talk to our team about making the right anti-tack formula for your tire manufacturing facility.

Contact EZ-Kote or call (770) 720-1811 for more details. We’ll respond within 24 hours.