Picking the Right Water-Based Mold Release

With the variety of materials and manufacturing techniques available today, it’s essential to select a mold release agent that meets your specific needs. EZ Kote

With the variety of materials and manufacturing techniques available today, it’s essential to select a mold release agent that meets your specific needs. EZ Kote

In food manufacturing, every component of the production process must meet rigorous standards. Maintaining strict hygiene and product integrity is non-negotiable, from ingredients to equipment.

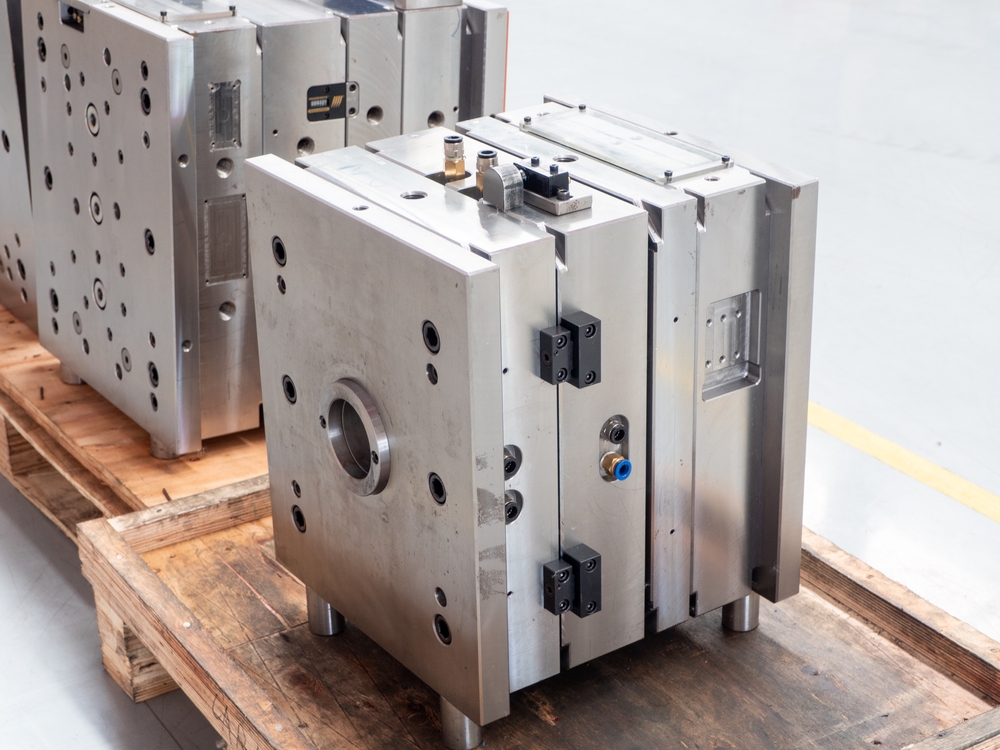

Compression molding is a technique for shaping raw materials like rubber, urethane, and composites. We’ll explore how EZ-Kote’s mold release agents contribute to streamlining compression

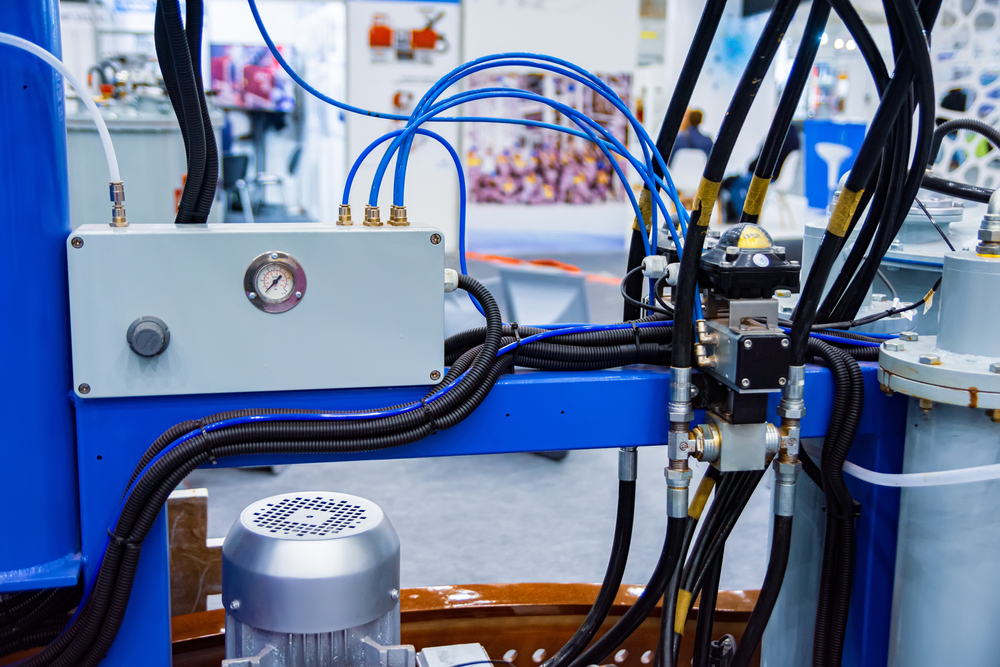

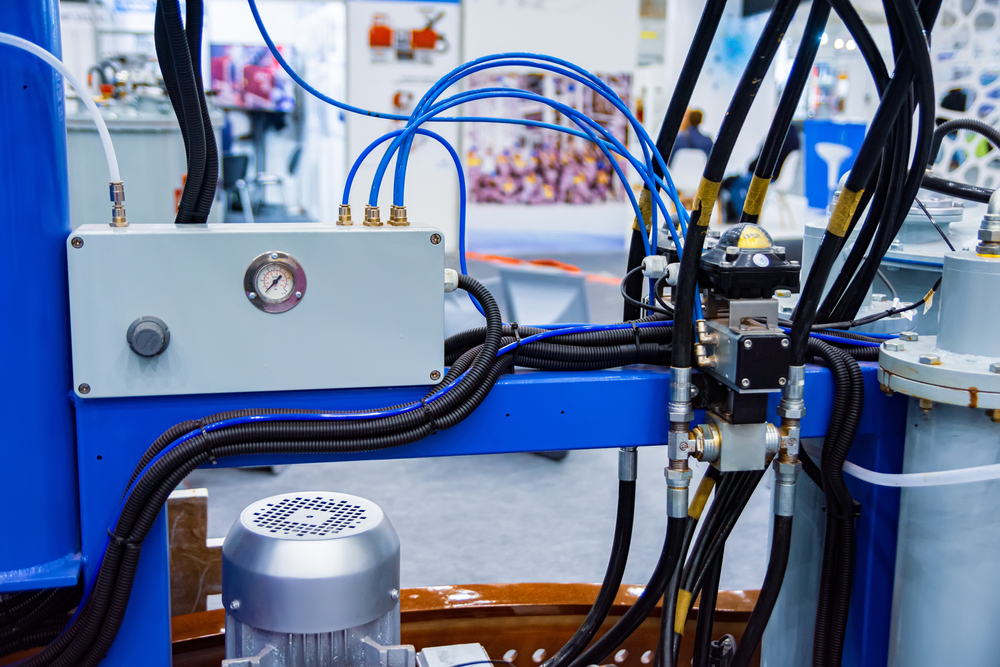

Mold releases are critical for injection molding. The right selection and application of mold release agents can help you achieve the best possible results in

Every detail matters when it comes to saving money and increasing efficiency in manufacturing processes. Using the right mold release agent, specifically custom water-based formulations,

Did you know mold releases can play a significant part in noise control? EZ-Kote’s water-based mold release agents are a key component in molding processes,

In this blog, EZ-Kote explains what anti-tack release agents are, explores their applications, and uncovers the many benefits of using the R1100 over traditional alternatives

Rotational molding has shaped the way we manufacture plastics. This process, also known as roto molding, offers unique advantages over other plastic molding methods. In

Are you still using a combination of cornstarch and talc for your industrial rubber mold release agent? We understand why. Cornstarch and talc are inexpensive,

Mold releases come in two primary forms for distribution: water-based and solvent-based. Water-based mold releases can be sprayed onto your molds because an atomizer evenly