Picking the Right Water-Based Mold Release

With the variety of materials and manufacturing techniques available today, it’s essential to select a mold release agent that meets your specific needs. EZ Kote

With the variety of materials and manufacturing techniques available today, it’s essential to select a mold release agent that meets your specific needs. EZ Kote

Every detail matters when it comes to saving money and increasing efficiency in manufacturing processes. Using the right mold release agent, specifically custom water-based formulations,

Did you know mold releases can play a significant part in noise control? EZ-Kote’s water-based mold release agents are a key component in molding processes,

Are you still using a combination of cornstarch and talc for your industrial rubber mold release agent? We understand why. Cornstarch and talc are inexpensive,

One key to mold release solutions is the fact they don’t react to their surroundings. When you invest in silazane or fluoropolymer-based mold releases, their

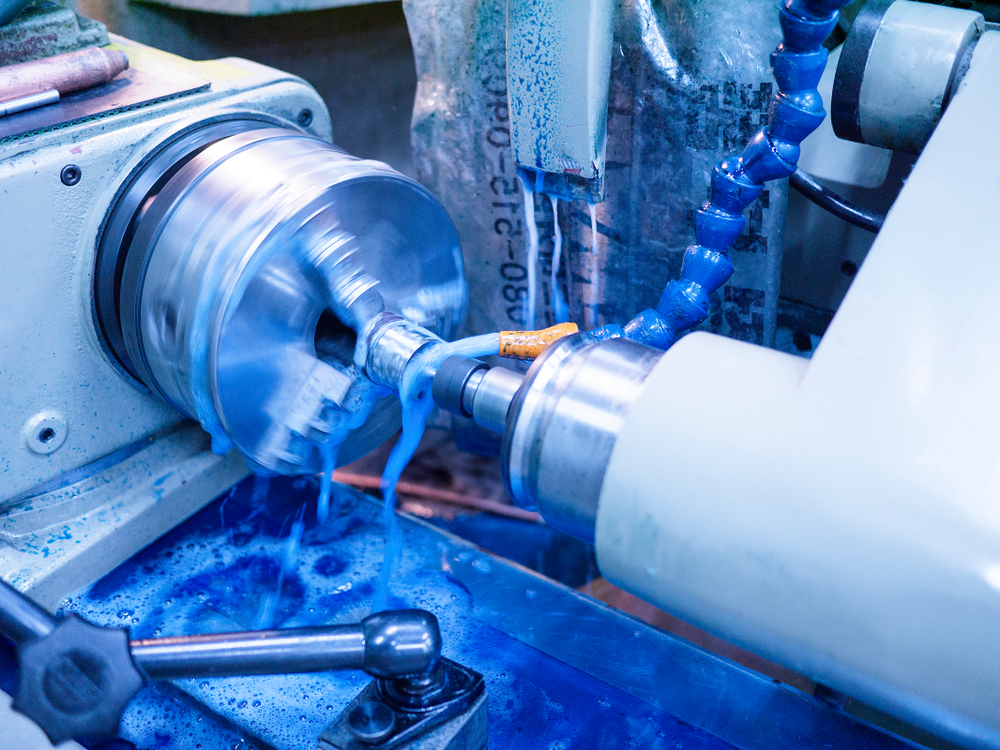

Water-based mold release agents help improve your industrial processes on several levels. They are composed of various chemical substances to give you better releases, fewer

EZ-Kote has been in the water-based mold release industry for more than 40 years. Our chemical engineers continue to innovate with research and development into

Water-based mold release agents are widely used in the manufacturing sector to achieve a surface finish, release control, and prevent oxidation. Water-based releases are safer

You want your investment in water-based mold releases to be as efficient and cost-effective as possible. As you’re QC testing your line for adding a

Water-based mold releases have several advantages over solvent-based mold releases or waxes. One of these advantages is a lack of volatile organic compounds (VOCs). These