How to Cure a Mold When Using a Water-Based Mold Release Agent

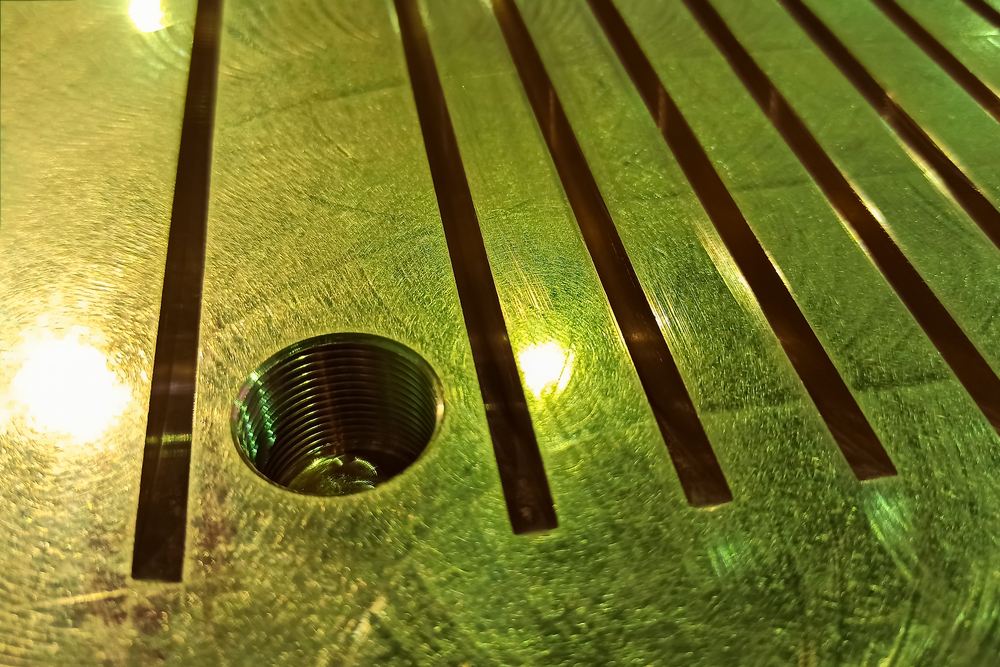

Water-based mold releases offer great ways to decrease shot cycle times, improve the performance of your molds, and reduce downtime when it’s time to change

Water-based mold releases offer great ways to decrease shot cycle times, improve the performance of your molds, and reduce downtime when it’s time to change

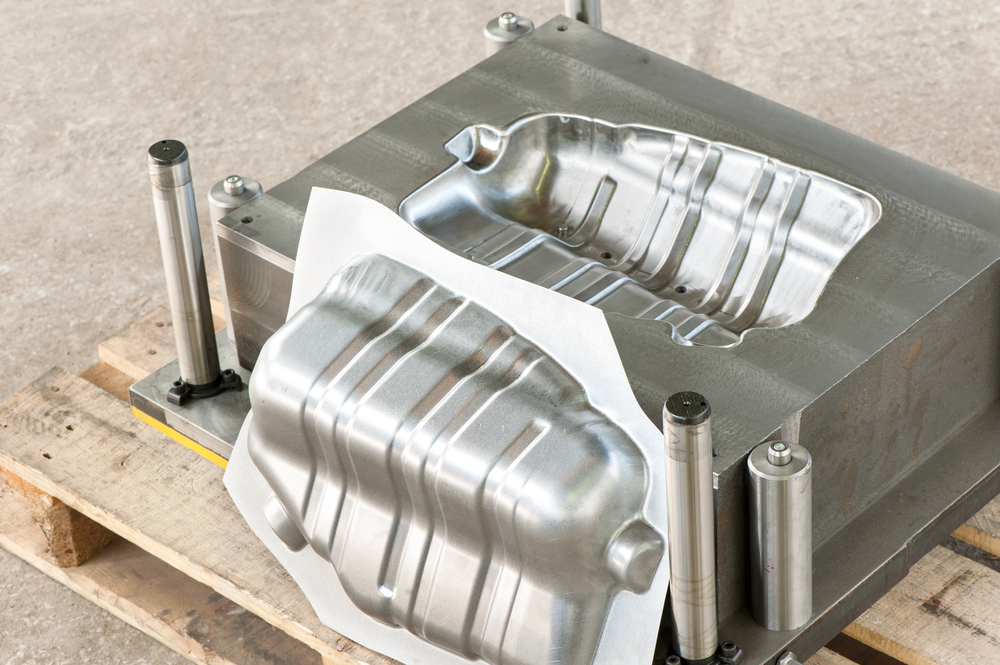

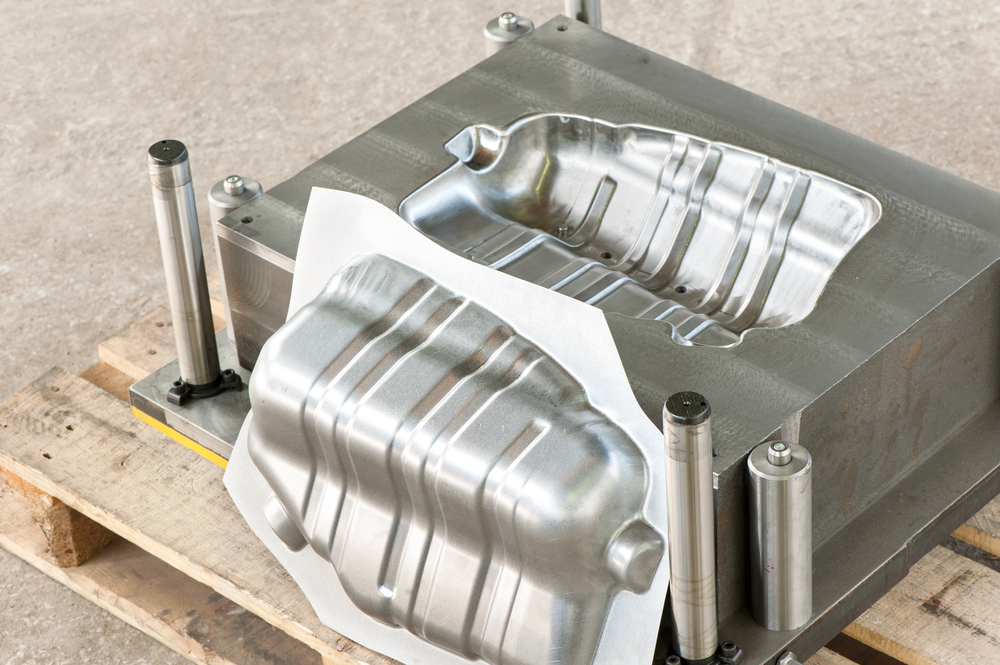

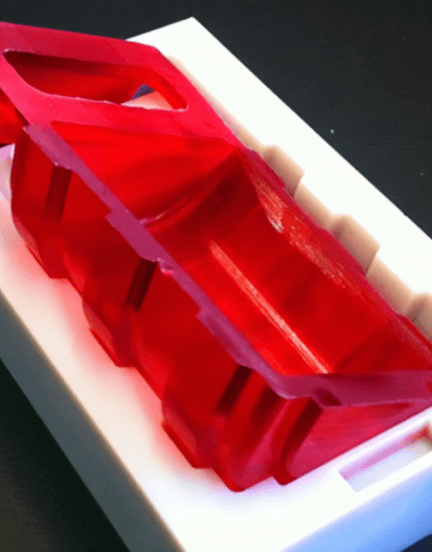

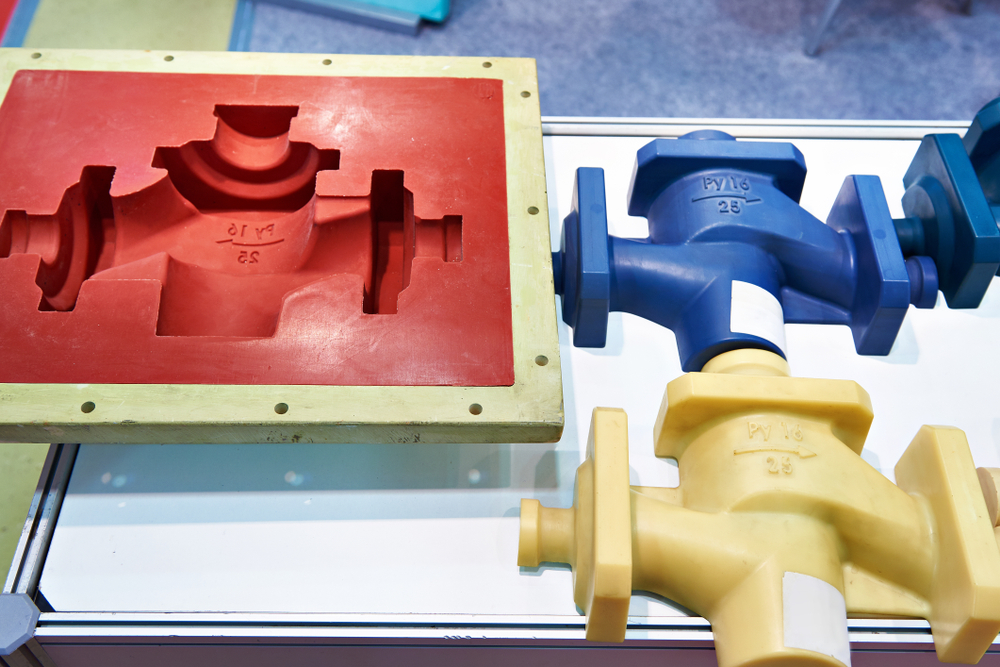

Urethane casting creates countless parts and products humans use every day. This industrial process has been around for decades, and manufacturers continue to refine how

Mold releases typically come in waxes or water-based forms. We specialize in water-based mold releases for your industrial processes. These environmentally friendly mold releases have

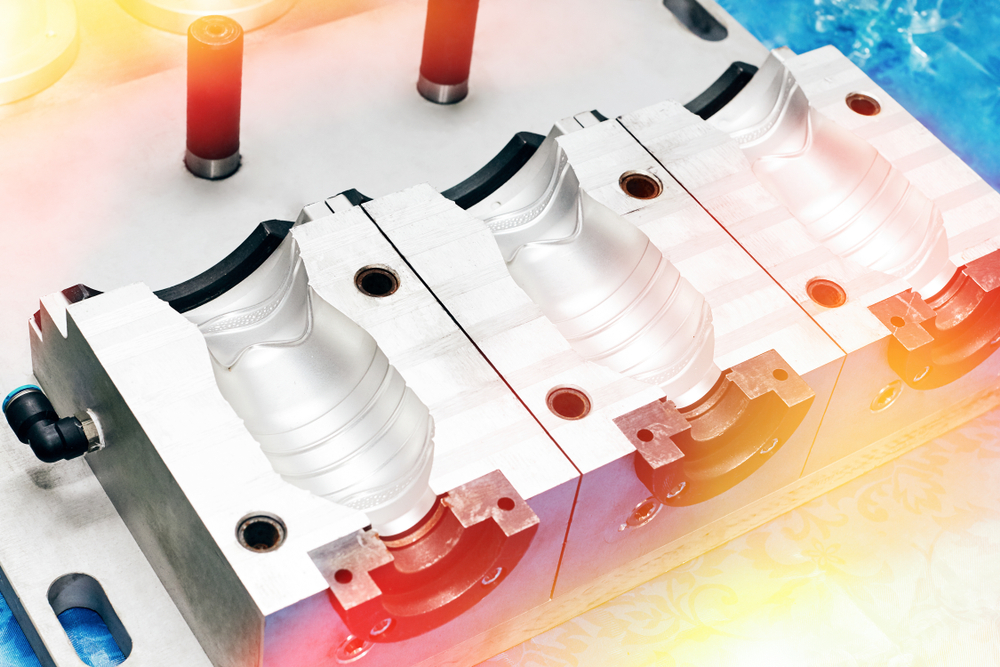

Mold releases for shoe sole manufacturing work for a wide range of processes at your factory. Our chemical engineers have been working on first-class mold

Mold releases can come in waxes and sprays. Waxes are generally more appropriate for resin molds, even though water-based mold releases are available for these

Mold releases come in two primary forms for distribution: water-based and solvent-based. Water-based mold releases can be sprayed onto your molds because an atomizer evenly

EZ-Kote provides a 21st-century solution for mold release applications with our environmentally friendly water-based formulas. We utilize state-of-the-art, semi-permanent, water-based technology that does better than

EZ-Kote provides a 21st-century solution for mold release applications. We utilize state-of-the-art, semi-permanent, water-based technology that does better than traditional mold release agents. We’re looking

EZ-Kote manufactures and provides world-class mold release agents to help make your industrial processes more cost-effective. In today’s blog, we discuss four key advantages of

EZ-Kote manufactures and provides first-class water-based mold release agents for industrial processes. We want you to get the most out of your mold release equipment.